How Electroplating Improves Busbars for EV Charging Systems & Infrastructure

This article covers how busbars are central to busbars are essential to efficient EV charging infrastructure, reducing space, installation time, and power losses, while electroplating improves conductivity, controls heat build-up, and protects against corrosion to ensure long-term performance in high-current charging systems.

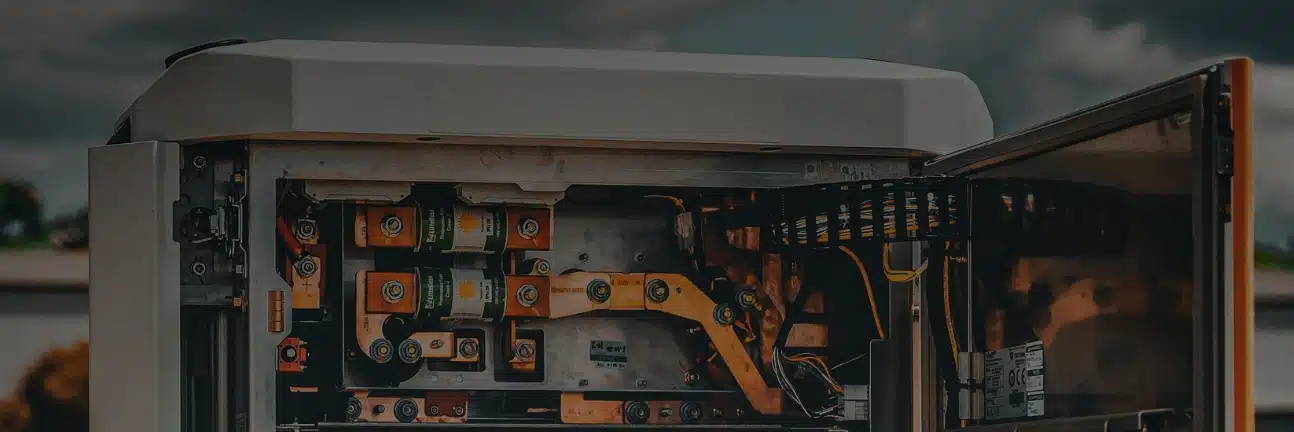

Electric vehicle charging infrastructure relies heavily on busbars. Common materials include copper, aluminium and laminated busbars, all of which play an essential role in delivering power across the growing range of charging installations, from AC Level 1 and 2 units to DC fast and rapid charging stations.

Busbars significantly reduce the need for large amounts of cable, helping sites save both space and installation costs. They also make future expansion easier. Many industry experts highlight that adding additional chargers later is far simpler with busbar systems than with traditional cabling.

Another major benefit is reduced installation time. Busbars create a more organised and predictable layout, which allows installers to work more efficiently and helps bring overall project costs down.

Busbars also offer larger cross-sections, shorter routes and fewer joints than traditional cables, resulting in lower power losses and improved efficiency.

Why Plating Matters for Busbars in EV Charging Infrastructure

Heat build up

The high currents required to charge electric vehicles can create issues with heat build-up. Opting for busbars reduces this risk, as busbars tend to carry more power and dissipate heat more effectively than conventional cables.

By using electroplated busbars, you can improve this further by enhancing thermal and electrical performance at the contact surfaces.

Better contact conductivity helps move heat away from joints and reduces hotspots. In some cases, coatings can even act as a thermal barrier.

Wider choice of material

Where weight is a consideration, aluminium busbars are often specified. They are lighter and more cost-effective than copper. Electroplating can improve their corrosion resistance and extends service life, making them more reliable for long-term use just liek copper busbars.

Compliance, Performance & Safety

Compliance is another important factor. Safety and performance requirements for EV charging systems are typically governed by regulations such as IEC/BS EN 61439 for low-voltage switchgear, assemblies and busbar systems. EV charging switchgear is usually designed and tested against these standards to ensure safe and reliable operation. They often specify key performance characteristics such as temperature rise, corrosion resistance and creepage/clearance distances. Looking ahead, it is likely that some standards will begin to specify particular finishes, making high-quality electroplating even more crucial.

Corrosion resistance

The characteristics provided by electroplating including corrosion resistance, improved contact performance, enhanced conductivity and solderability, can reduce long-term maintenance and service costs. By improving the durability and performance of busbars, electroplating helps minimise the frequency of replacement or repair, lowering whole-life costs for operators.

Electroplating helps protect the underlying metal, extending the busbar’s lifespan and ensuring reliable operation, particularly in outdoor environments where moisture and pollutants accelerate corrosion.

Finishes for Charging Infrastructure

Silver-plated copper busbars

Silver plating on copper busbars is ideal for the environments in which most charging infrastructure operates. This combination offers excellent corrosion resistance while maintaining the high conductivity necessary for fast and reliable power transfer.

Nickel plating

Nickel provides a hard, corrosion-resistant surface ideal for harsh environments. It is often used as an underlayer beneath tin or silver to improve durability and adhesion.

Tin plating for busbars

Tin-plated copper busbars offer a cost-effective contact surface for switchgear, panels and EV charging systems. Tin plating prevents copper oxidation, maintains low contact resistance and reduces galling at bolted joints. In higher-temperature or high-frequency applications, tin plating stacks or nickel underlayers may be specified to manage risks such as whisker formation or thermal stress.

Nickel, silver and tin

Nickel, silver and tin plating are suitable for improving contact performance and ensuring long-term reliability of busbar systems.

How Karas Plating Can Help

When it comes to busbars and material selection, we know that the coating method you choose directly affects electrical performance and durability. This is why Karas offers a range of specialist electroplating processes specifically suited to busbars used in EV charging infrastructure.

- We have a team of experts on hand to ensure you always have the correct plating solution for your defined, in advance of processing your busbars.

- We have experience in providing high quality finishes making sure the deposited coating forms a strong, reliable, and functional part of the base material, rather than just a superficial layer.

- Full capability to support prototypes, trials, and validations with necessary industry qualification, such as PSW / PPAP.

- We operate a lean production system, this ensures that parts are plated consistently, quickly, and efficiently, minimising cost, and providing reliable lead times.

- We have invested significantly in state-of-the art cleaning, plating, and testing equipment to complement our lean systems.

- Our most important asset is our people, with an average of fifteen-years’ service, our experienced team take pride in everything they do.

- We are fully RoHS and REACH compliant so you can have confidence in your products and supply chain

- We are agile and can build (in-house) specific process lines to suit most applications.

- Our processes and team have received full certification and approval in all key metal finishing areas, including but not limited to, ISO 9001 (Quality), ISO 14001 (Environmental) & ISO 45001 (Health & Safety).

- Our practical knowledge in metallurgy can help you predict how your electroplated busbar components will perform under specific conditions, including corrosion, electrical conductivity, hardness, and wear resistance.

- We also provide custom plating options, such as tin plating available in bright or matte finishes and Nickel plating, including electroless nickel and electrolytic nickel. These are useful when it comes to plating stacks and underlayers.