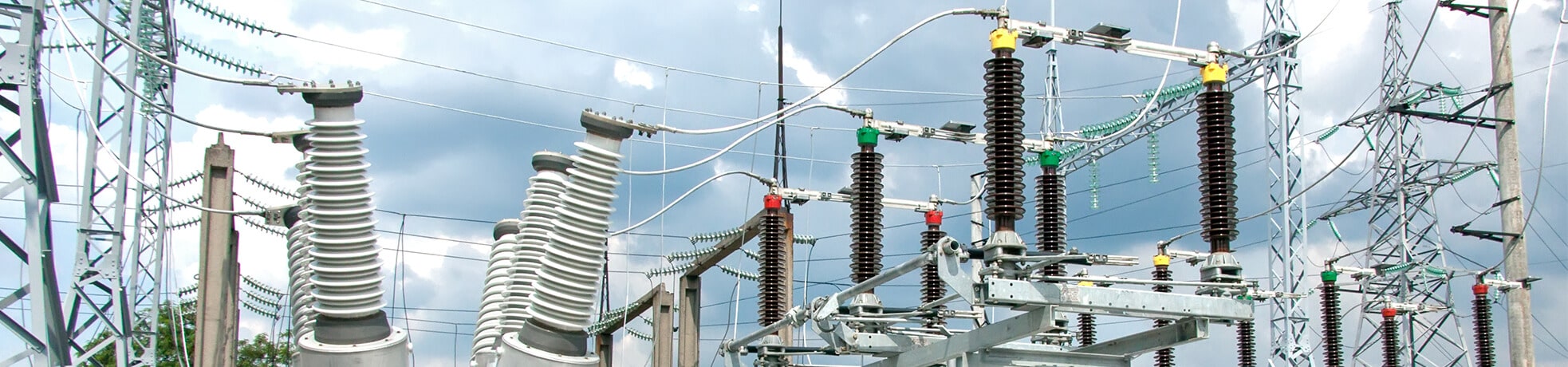

If you work in the electric power distribution industry, you will already know what a busbar is. Typically housed within panel boards, switchgear, and busway enclosures, these simple metallic strips are an effective and flexible method of electricity distribution. They are also found connecting low voltage equipment in battery banks, as well as high voltage equipment in electrical switchyards.

Considering the important role they play in power distribution, they are a remarkably simple tool, being little more than strips of copper, aluminium, or brass designed to both conduct and ground electricity.

As simple as they are, they still require protection, and the best way to do that is by having them plated.

Why do bus bars need plating?

Many busbars are made from copper, already resistant to corrosion and rust. However, this doesn’t mean that it won’t oxidise over time. Given its importance in power distribution systems, having a bus bar break unexpectedly could have serious consequences. Quite aside from increasing its longevity, plating is important so that the conductive service of each busbar maintains its integrity.

Conductive integrity is key to the proper functioning of a bus bar. As the copper oxidises, more power is needed to transmit the electricity across the pitted and flaking surface. This makes it less efficient as a distribution system both in terms of speed and cost.

What metal is used for the plating?

Opinion is divided on the subject. Some plating companies prefer tin, while others favour silver. Both metals serve a similar purpose, and each has its positive and negative points.

Here at Karas Plating, we use silver for plating busbars. Highly conductive and naturally resistant to many chemical substances, it is the perfect solution for bus bar plating. Whilst a more expensive metal to work with, plating with silver requires less raw material than plating with tin. This allows us to plate even the smallest busbar components with silver, should the need arise.

Quality silver plating

When plating bus bars, the goal is optimal conductivity – it’s the entire purpose of these electrical components. At Karas Plating, we use silver with a 99.9% purity for plating any items expected to experience high levels of electricity or heat. This, of course, includes busbars. This level of purity is higher than you would find in most commercial jewellery or decorative silver plating. It ensures maximum performance and efficiency.