We have been in the silver plating business for more than seventy years here at Karas Plating. In that time we have earned ourselves a well-deserved reputation amongst our customers up and down the UK for the high quality of our workmanship and the professionalism of our staff. Silver is an incredibly useful metal with which to plate, having many qualities beneficial to a host of industries across the country.

What is silver plating?

Like many electroplating processes, silver plating involves creating a circuit within an electrolytic solution that will transfer microscopic particles of silver from a source to your substrate material. It can be quite a slow process, but one that produces highly effective results.

How does silver plating work?

In the silver plating process, 99.9% chemically pure silver anode is used in an electrolytic solution.

The components to be plated must first go through initial cleaning stages and then be suspended in the solution.

An electrical current is then introduced to grow the surface to the desired thickness of the plate. This process helps to achieve a uniform and durable silver coating on the components.

Visual Appeal

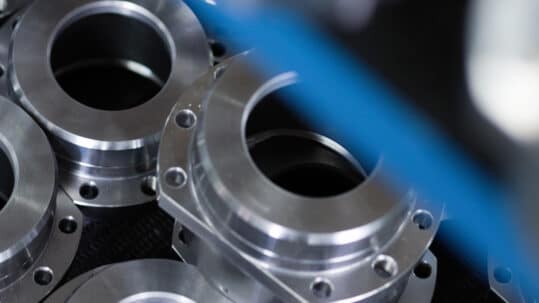

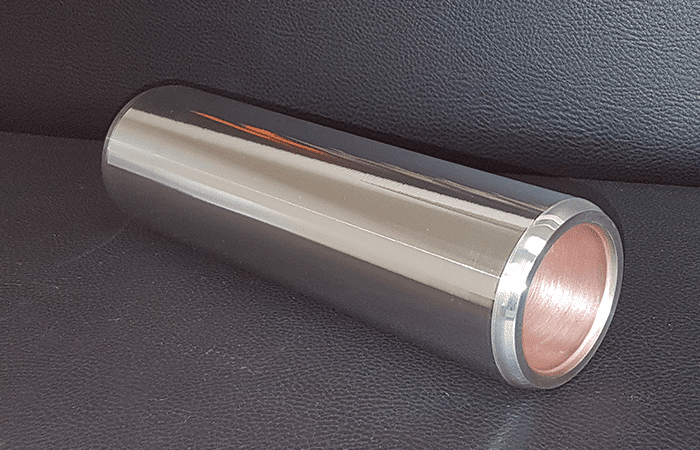

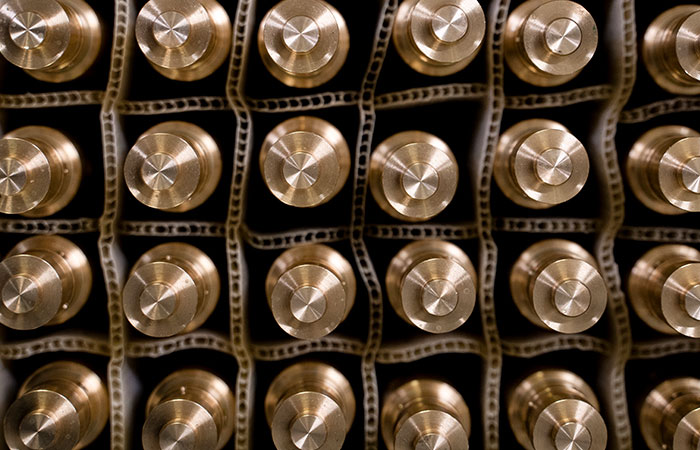

The appearance of silver plating can vary from a bright and shiny look to matte depending on the brightener level in the solution. This makes silver plating very popular for aesthetic purposes.

Applications of the silver electroplating process

However, aside from purely cosmetic effects, silver plated components have a wealth of applications across numerous industries.

Silver has natural antibacterial properties, making it an excellent choice for cookware and the medical sector, where clients opt for a silver finish due to its resistance to bacteria and germs.

Silver is naturally resistant to numerous chemical substances and is the single most conductive material commonly used in electroplating. This makes it an attractive proposition for many industries including automotive (particularly as part of exhaust systems), rail, power generation, industrial, and domestic.

Benefits of the silver plating process

Silver electroplating technology imparts several excellent properties to base metals. It is highly resistant to a number of common chemicals and is remarkably heat resistant.

Even at high temperatures, good quality silver coating does not oxidise or degrade, which makes it an ideal material for high-temperature environments, such as the power generation industry. Likewise, its remarkable anti-galling and anti-fretting properties (thanks largely to the great lubricity and low friction it exhibits) are not affected by high temperatures either making it a perfect solution for the automotive industry.

It is also worth noting that silver is one of the best metals for conducting electricity, making it an efficient solution for many electronic companies.

a quality process

Just like the rest of our metal finishing techniques, all silver electroplating processes at Karas Plating are carried out in compliance with ISO 9001 standards for Quality and ISO 14001 standards for Environmental. What this means for you, our customers, is plated components of the very highest possible quality.

Latest Resources