A history of electroplating: from 1970 to the modern day

Our last instalment in the history of electroplating took us from the mid-Victorian era to 1969. Many of those old techniques are still applicable today, as the fundamentals have not changed. Indeed, the Elkington plating company is still a respected manufacturer of gold-plated dinnerware. All that’s really changed is the sophistication of the processes.

With that said, let’s finish off this history by bringing us up to the modern day…

The Silicon Age

1970 saw the birth of the Silicon Age – of which our current Digital Age is still a part. This brought with it the need for better processes to account for the small components and circuitry essential to the electronics industry. IBM began using electroplating in its computer chip production during the 1970s, as well as older damascene techniques. In the decades that followed, gold electroplating was also used on the electrodes in fuel cells, as well as circuit board contacts. These days, gold-plating isn’t the only process the industry uses – it makes use of other metals for things such as protective coatings, contacts and other applications.

Electroless plating

It seems counter-intuitive, but metal plating without the benefit of electricity is a comparatively recent development. The possibility had been considered in the mid-19th century, but never put to industrial use. In 1944 Abner Brenner and G.E. Riddell discovered the process for a second time, entirely by accident. They had been experimenting with different currents, substrates, and additives to the solution, without much success. At some point, they disposed of the current and realised that they could plate nickel using sodium hypophosphite. The sodium hypophosphite acted as a source of electrons, rather than the electric current. Electroless plating is today used for many applications and involves many different metals, including cobalt, copper, silver, gold and more.

With the Gilded Revival over, we were about to start the Silicon Age, where electroplating would again prove invaluable.

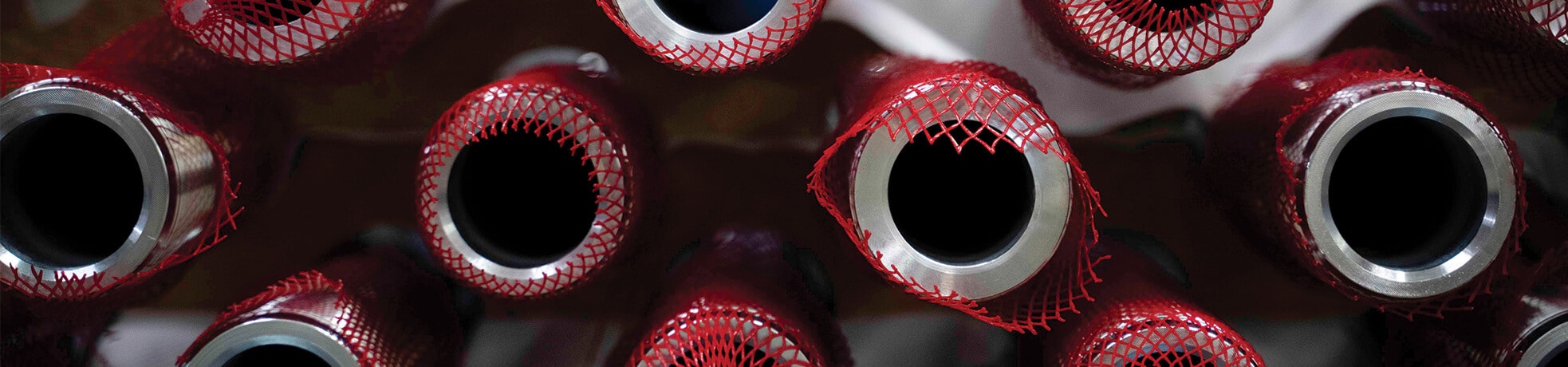

Non-metal substrates

A major innovation in the last few decades is the ability to plate non-metal surfaces. Something that would have been unthinkable during the early days of metal plating is now commonplace. It is even possible to plate materials as diverse as glass, plastic, ceramic and Kevlar. Using a non-metal substrate offers certain advantages. For instance, plated plastic is considerably lighter than solid metal, while sharing the same strength and durability. This makes it invaluable in the automotive and aeronautic industries, among others.

Which brings us to the modern day. What developments will occur in the electroplating industry in the future? How many innovative new applications will it enable? Nobody knows. We do know one thing – whatever the changes, Karas Plating will be right there at the cutting-edge for all your plating needs.

Reread past instalments on the history of electroplating

-

A history of electroplating: from Bronze Age to Medieval

Electroplating feels like it should be a modern phenomenon, but nothing could be further from the truth. Explore part 1 of the history of electroplating....

-

A history of electroplating: from the Renaissance to the Victorian Era

Join us as we look at the major developments in electroplating, from the Renaissance to the Victorian Era....

-

A history of electroplating: from the 1850s to the Gilded Revival

Join us as we look at the major developments in electroplating, from mid-Victorian England to the 1960s....

-

A history of electroplating: from 1970 to the modern day

Join us as we look at the major developments in electroplating, from 1970 through to the modern day....