The hungry sea: the importance of high build copper plating in the petrochemical industry

Of the many commercial and industrial sectors we supply with high-quality plating solutions, the petrochemical industry presents some of the most unique challenges. There are certain processes and techniques that we apply that are commonplace across almost all sectors. These include gold plating and silver plating for electronic connections, as well as nickel and zinc plating to prevent corrosion.

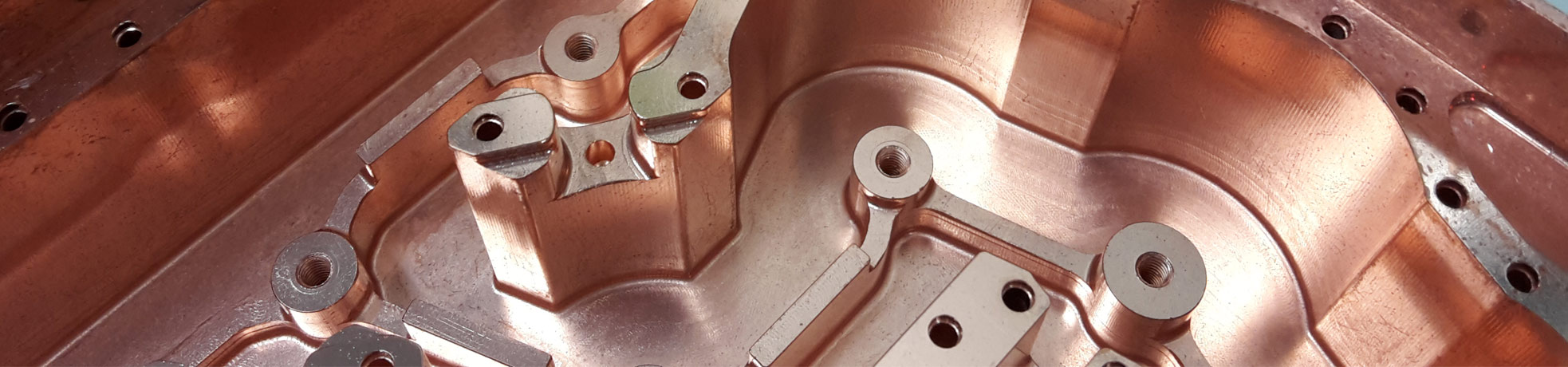

Both of these plating processes – and many more everyday applications – are used by the petrochemical sector as well, of course. However, one of the most interesting (and the most important) solutions we provide is high build copper plating.

So why is it so important?

Let’s take a look…

What is high build plating?

High build plating is simpler a thicker layer of metal on top of the substrate. It can be used with several metals, including silver, nickel, tin and, of course, copper. The longer you leave the substrate in the plating solution, the thicker the coating.

Why is marine growth a problem

In a word – corrosion. Both plants and animals that adhere to petrochemical equipment excrete acids and salts into their immediate surroundings.

Without high build copper plating to discourage them, those immediate surroundings include the metal components of the company in question.

Over time, they are subject to higher levels of corrosion, which are expensive and difficult to repair.

Why is copper so important to the petrochemical industry?

The petrochemical industry uses oil and gas rigs, drills, and pipelines that spend most (if not all) their time beneath the ocean’s surface. This makes them a natural target for marine growth. Marine growth is a catch-all term referring to various animals and plants that adhere to solid surfaces underwater as part of their normal life cycle.

These include algae and seaweed, as well as barnacles, mussels, limpets, and other shellfish. A layer of high build copper plating helps to protect these components as marine growth does not like to attach itself to copper. The metal produces a chemical reaction that these living creatures find unpleasant. You can see the same thing with copper strips being used to deter slugs in the home.

Why does it need to be a high build copper plating?

Despite what Disney’s The Little Mermaid would have you believe, it is not a pleasant life under the sea. Quite aside from preventing marine growth, the copper plating we apply needs to be thick enough to handle constant battering on all sides from tons of sea-water. While we pride ourselves on the quality of our regular plating processes, in the inhospitable deep only the added thickness of a high build copper plating solution will do.