How Electroplating Supports the High-Power Electric Vehicle Busbar Market

As electric vehicles move towards higher voltages and faster charging, busbars are under increasing pressure to deliver reliable performance. Electroplating helps by improving conductivity, durability, and resistance to heat and corrosion, thereby making busbars safer and more durable. We support manufacturers with tailored finishes that meet the demanding requirements of modern EV systems

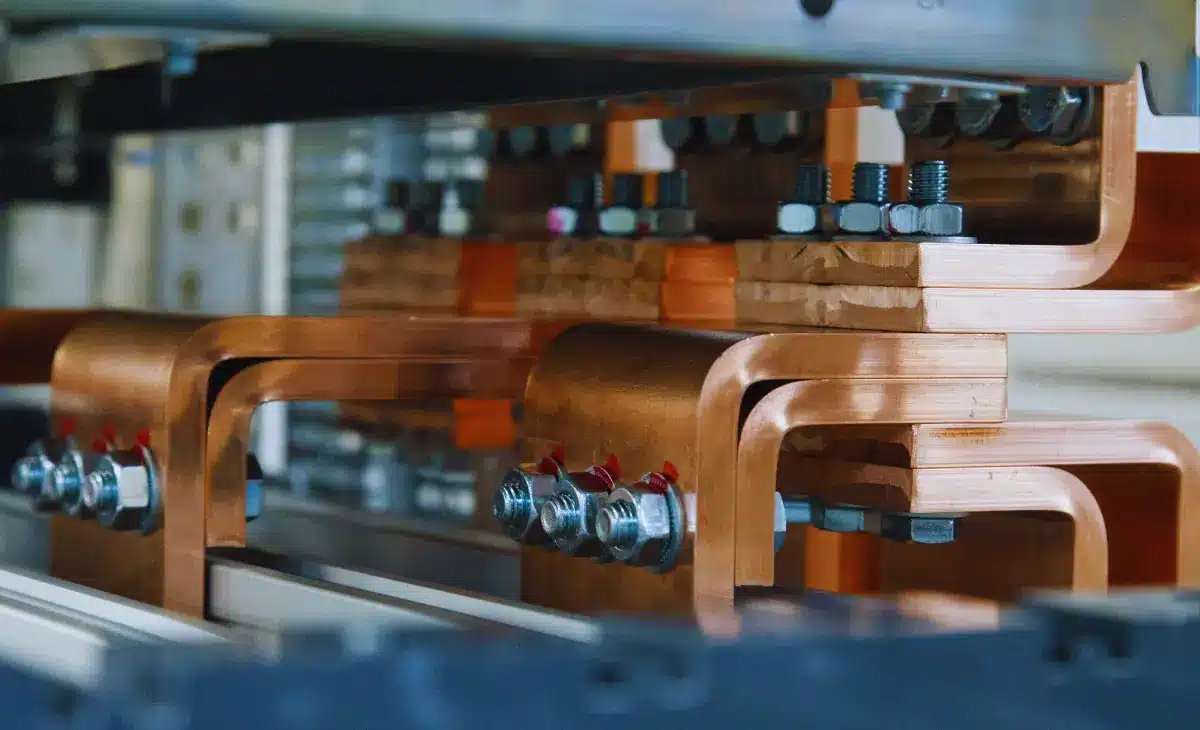

The growing demand for electric vehicles (EVs) continues to drive significant change in vehicle architecture and component performance. One area that’s receiving considerable attention is the power distribution system, particularly the use of high-power busbars.

Busbars play a central role in managing electrical flow between batteries, inverters, and other high-voltage systems. As EV technology pushes towards higher voltages, 800V systems are becoming more common, busbars must handle greater electrical currents and increased thermal loads. Electroplating has become a key part of the solution, enabling manufacturers to meet performance, safety, and reliability expectations.

We’ve worked with clients in automotive and advanced manufacturing for decades and witnessed first-hand how crucial the right finish can be for high-performance components, especially as the EV sector grows rapidly and brings with it new challenges.

Electroplated Finishes Ensure Busbar Reliability for OEMs and Tier 1 Suppliers

Many OEMs and Tier 1 suppliers require busbars to meet strict performance standards, including resistance to thermal cycling, vibration, and corrosion.

Meeting the Demands of Modern Busbar Design

The main purpose of busbars is to distribute electricity in systems that require high current. They are commonly found in various industrial applications, including facilities, power plants, and substations.

Busbar materials

With advances in base materials like copper and aluminium, there’s now more choice in how busbars are designed. Copper is still preferred for its excellent conductivity, but aluminium is gaining ground due to its lower weight and cost. However, aluminium is highly susceptible to oxidation, which impairs its conductivity. Plating aluminium busbars, especially with nickel, is essential to improve their oxidation resistance and ensure they perform reliably in demanding EV environments.

Whichever base material is chosen, electroplating allows manufacturers to enhance conductivity, durability, and resistance to corrosion. This is especially critical in the automotive sector, where components must maintain consistent performance under constant mechanical and thermal stress.

Enhancing Conductivity

The core function of a busbar is to control and connect electrical power between key systems in a vehicle. Silver plating is widely recognised for offering the highest level of electrical conductivity. It also has excellent thermal conductivity, making it particularly suitable for high-power EV busbars that must move significant amounts of energy quickly and efficiently.

Electroplating processes like silver plating improve the electrical performance of both copper and aluminium busbars, helping vehicle manufacturers meet high power demands while maintaining reliability over time.

Managing Heat

Thermal management is another major consideration. High-voltage EV systems generate a great deal of heat, which must be managed to avoid failures such as overheating or material breakdown. Electroplating helps by improving the thermal properties of the busbar surface. A correctly plated surface can dissipate heat more efficiently, reducing the risk of hotspots and supporting stable performance even under heavy load.

Reducing Contact Resistance

Over time, resistance at contact points can lead to energy losses and inconsistent electrical flow. This is particularly problematic in high-current systems like those found in electric vehicles. Plating processes such as tin and silver provide low contact resistance, which is crucial for minimising energy loss over the lifespan of the system. These finishes also improve the reliability of connection points within the busbar network.

Improving Durability

Busbars must also withstand vibration, thermal cycling, and mechanical stress conditions that are common in EVs. Nickel plating, for example, adds hardness and wear resistance to the surface of a busbar. This extends service life and improves overall mechanical durability, ensuring that parts continue to perform as intended throughout the life of the vehicle.

Supporting Connections and Joints

Plated finishes also support the formation of reliable joints and interconnections. Tin plating is especially useful in this area, as it improves solderability and helps create consistent, low-resistance joints. For EVs, where compact design and long-term reliability are essential, these joints must be as reliable as the busbar itself.

Ensuring Performance in Harsh Conditions

EVs are often exposed to extreme conditions such as high and low temperatures, moisture, road salt, and other environmental factors. Corrosion is a real risk, particularly for busbars without any insulation or protection. Electroplating offers a reliable solution. Nickel and tin coatings protect against corrosion and oxidation, making busbars safer and more dependable across a wide range of environments.

For more insights on the importance of busbar plating in the age of EVs, read our dedicated article on Busbar Plating in the Age of Electric Vehicles

Supporting the Shift Toward Customisation

As EV platforms become more specialised, the need for customised busbar electroplating solutions increases. Here at Karas Plating, we now plate busbars up to 4.2 metres in length, a good example of how we’ve adapted to support evolving manufacturing requirements. Busbars are no longer one-size-fits-all. Shapes, sizes, and specifications vary significantly, and the plating process must be just as flexible to achieve the right outcome.

Whether you’re working with low-volume prototypes or large-scale production, we have the capacity and systems in place to deliver consistent quality at scale.

Innovations in electroplating processes and materials are helping manufacturers develop the next generation of lightweight, high-performance, and safe busbars. As the use of both copper and aluminium continues to grow, and as systems demand higher power and faster charging, the finishing process becomes even more important.

If you’re developing high-power electric vehicle busbars, improve grid connection for electric vehicle charging infrastructure systems and want to ensure optimal conductivity, durability, and reliability, we’re here to help. We’ll work with you to find a solution that fits your technical requirements and production needs. We regularly work alongside engineering and procurement teams to advise on finishes that best suit the application, helping to reduce issues later in production.