Cost Savings with Nickel-Tin Plated Busbars

For manufacturers and buyers of busbars – cost is a crucial factor. Selecting the right plating material directly impacts overheads, durability, and performance. While materials like silver and gold offer excellent conductivity and corrosion resistance, their high cost often makes them impractical for large-scale applications.

In this article, our plating team will explore how nickel-tin plating delivers a cost-effective alternative to precious metal coatings like silver and gold for busbar applications—without sacrificing performance or reliability.

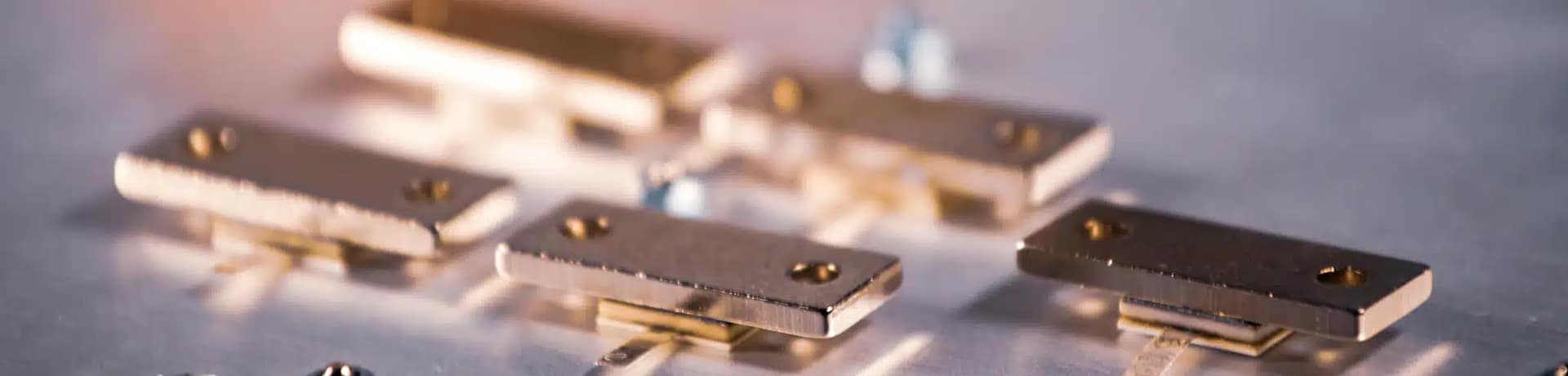

Dual‑layer nickel–tin electroplating is commonly used on copper and aluminium busbars to combine tin’s low cost and good contact behaviour with nickel’s hardness and barrier properties.

Why Nickel and Tin Plating is a Cost-Effective Choice

Nickel and tin plating provides a more economical alternative without compromising on quality.

Aluminium Busbars: The Need for a Base Layer

Due to their reactive nature, including oxidisation, aluminium busbars cannot be directly plated with tin or silver. A base layer (substrate) is required to ensure adhesion and durability. Nickel serves as an excellent intermediary layer, enabling effective tin plating. This combination not only improves conductivity but also enhances corrosion resistance, making it a reliable and cost-efficient solution.

Copper Busbars: Enhancing Perfomance

As highly conductive as copper busbars are, they are prone to oxidation and corrosion, especially in demanding environments such as high‑temperature applications, automotive, and humid or chemically active atmospheres. Electroplating is often required to maintain long‑term electrical performance and reliability.

Plating copper busbars with a combination of nickel and tin provides a highly durable busbar with a balance of protection and electrical performance. The nickel underlayer acts as a barrier and offers excellent high‑temperature stability, corrosion resistance, and mechanical durability. Over this, the tin top layer provides a low‑contact‑resistance, solderable surface that resists oxidation and reduces the formation of insulating copper oxide films.

The combination improves contact reliability, helps maintain low contact resistance, and extends service life, making nickel‑under‑tin plated copper busbars a preferred choice for many industrial and automotive power‑distribution systems.

Reducing Costs with Nickel and Tin Plating

Unlike costly alternatives like silver and gold, nickel and tin plating offers a budget-friendly approach. Tin, in particular, is significantly cheaper while still delivering excellent conductivity and corrosion resistance. Nickel, when used as a base layer, ensures strong adhesion and a dense, corrosion-resistant surface. This combination is particularly advantageous for:

- Aluminium busbars – Achieving a reliable plated surface without the high cost of alternative metals.

- Copper busbars – Providing enhanced durability and heat resistance for high-temperature applications.

Use nickel plating to reduce the risk of tin whiskers

One common issue with tin plating is the formation of “tin whiskers”—tiny, hair-like structures that can cause short circuits in electronic applications. According to research, the nickel base layer significantly mitigates this risk by acting as a barrier, effectively delaying and reducing whisker growth. This added reliability translates to long-term cost savings by minimising the need for more frequent maintenance and replacements.

Extended Lifespan and Lower Maintenance Costs

Nickel and tin-plated busbars require less routine maintenance compared to uncoated or alternative metal finishes. The superior wear resistance and durability provided by this plating combination reduce the frequency of replacements, further cutting down costs over time..