Meeting Medical Manufacturing’s Highest Surface Standards

The medical industry makes enormous use out of various metal finishing techniques, and with good reason. After all, medtech companies and manufacturers insist on flawless quality in their machine’s components. While high standards are essential in any sector, with medical equipment it can literally be a matter of life or death.

Electrical components need to be plated with precision to ensure accurate readings for diagnoses. Metal tools and instruments must be free of defects to prevent injury or damage. Of course, all surfaces must be free of contaminants to avoid the spread of infection.

Plating improves a component’s surface without altering the underlying material. It allows manufacturers to add biocompatibility, corrosion resistance, or electrical performance exactly where it is needed.

As the North West’s top metal finishing company, Karas Plating has been supplying the medical industry with top quality plating solutions for decades.

Electroplating processes for Medical Devices and Diagnostic Equipment

Here are just some of our processes and how they have been put to good use.

GOLD PLATING

A chief attribute of gold, when considering its use in the medical sector, it its biocompatibility. Simply put, it poses no risk of causing a harmful reaction if exposed to human tissue. It is also an excellent conductor of electricity, an important consideration for precision medical equipment. Since it is also resistant to corrosion and abrasion, it is often used in internal medical equipment, such as pacemakers and artery stents.

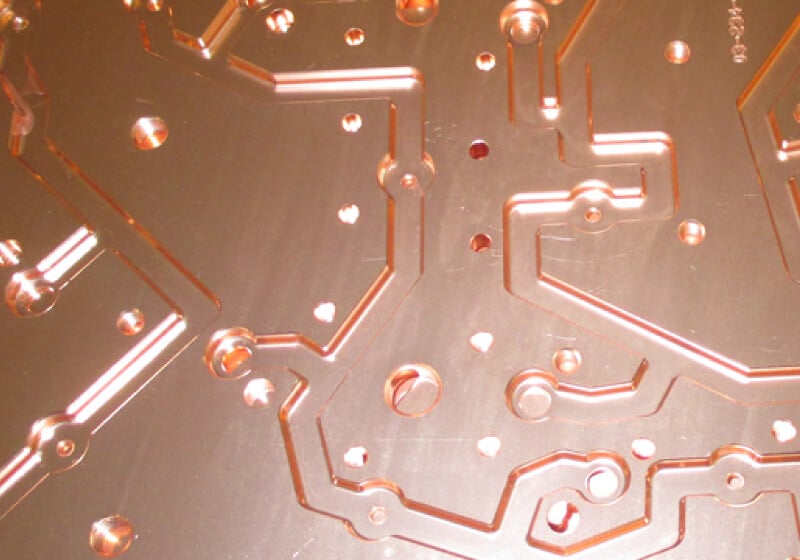

COPPER PLATING

Like gold, copper is a fine conductor for electricity. It performs well when exposed to high temperatures, making it useful in many medical machines. While not sterile enough to risk in medical implants, the metal boasts many bacteria-resistant properties. This makes it a prime choice for medical and laboratory equipment.

NICKEL PLATING

Nickel serves as a good undercoating for gold plating, adding strength to and components that use this technique. It is a ductile metal, with high corrosion-resistance, making it a good choice for applications requiring electrical contacts.

ELECTROLESS NICKEL PLATING

Electroless nickel plating coats components via a chemical reaction, without the use of electricity. The process provides a thin, uniform coating, essential to many medical applications.

SURFACE PREPARATION AND CLEANSING

As well as the finishes we apply, we also perform in-depth surface cleaning processes to rid the base materials of all contaminants. With the need for sterile equipment in the medical industry, this process is essential.