Even though busbars can technically be specified without any surface treatment processes. Due to various environmental factors and the demands of modern electrical systems, there is an increasing need for improved conductivity, thermal performance, durability, safety, and long-term reliability, especially at joints and contact points. This highlights the importance of applying surface finishing to these conductors.

Why Surface Finishing Is Essential for Busbar Performance & Reliability

These factors cannot be addressed solely by base material selection, which is why surface finishing and plating are vital for the performance and reliability of busbars.

In this article, we examine why busbar electroplating is widely used across industrial applications and the role it plays, focusing on factors beyond conductivity alone. We explore how surface finishing enhances functional performance, supports compliance, reduces maintenance and safety risks, and enables material optimisation by reducing material usage. We will also consider the operational and economic benefits of surface finishing treatments for busbars.

Enhance conductivity

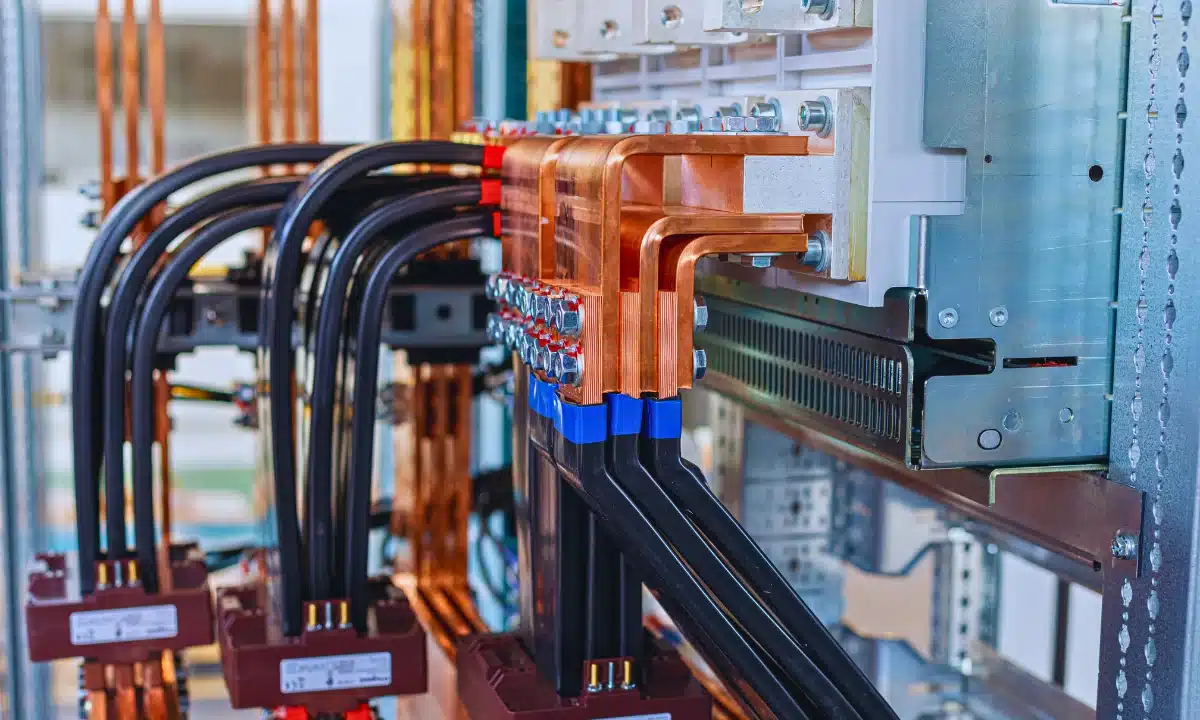

As busbars store and transfer large amounts of current through various systems, conductivity is critical to improve efficiency, minimises energy loss, and maximise performance.

Copper is a popular choice when it comes to busbar material but there are many use cases where (a) higher conductivity is required and/or (b) using bare, uncoated metal risks an unacceptable amount of oxidation, which we will discuss further below.

Therefore, plating copper busbars is an alternative way to achieve improved electrical conductivity and overall power system performance. By applying a silver-plating process, manufacturers can significantly improve contact conductivity and help maintain low resistance under load thanks to the excellent conductivity of silver. This makes silver-plated busbars particularly well-suited for high-voltage applications.

Maintain low resistance

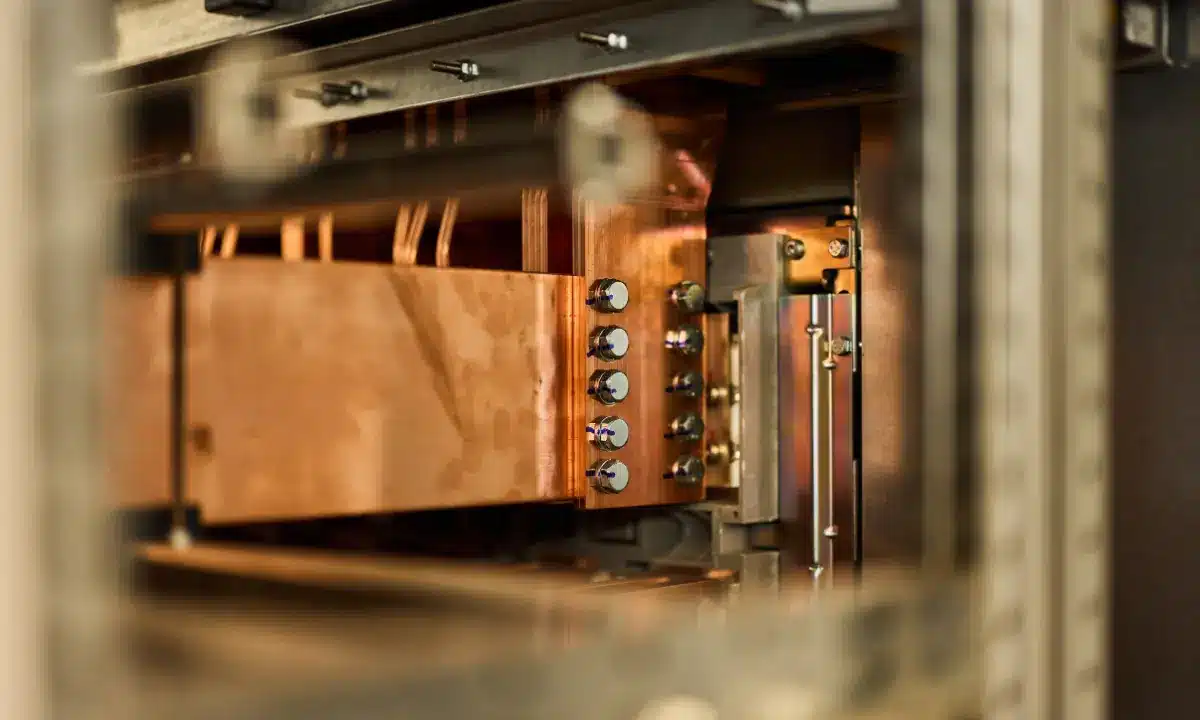

For contact points to maintain more efficient power transfer and prevent overheating, electroplating helps busbars maintain low resistance, which is crucial for electrical connections. Tin plating processes for busbars enable stable contact resistance and a low maximum operating temperature. This reduces resistance at joints and improves long-term electrical performance.

Prevent oxidation

Oxidation, a form of corrosion, is common on copper busbars and occurs when busbars are exposed to air and other environmental elements, forming a layer on the surface of the copper. Installations operating in harsh environments, such as marine, infrastructure, and data centre environments, are more susceptible to busbar oxidation.

This oxide film causes problems, such as increased electrical resistance, which affects the performance of the busbar and therefore the wider system in which it operates. This increases maintenance costs, impacts safety, and increases the risk and duration of downtime in applications where uptime is critical, and every second counts.

Surface treatments such as nickel and tin plating prevent oxidation by forming a layer that acts as a physical barrier to protect the base metal. This barrier helps separate oxygen, moisture, and other environmental factors from the busbar. This is one of the main reasons why tin-plated busbars are a go-to choice for electrical distribution needs.

For more demanding applications, dual-layer plating can be utilised, starting with nickel as the undercoat and then applying either tin or silver on top. The nickel undercoat enhances the hardness and wear resistance of the components, which is crucial for sliding contacts. Additionally, the nickel layer acts as a diffusion barrier, helping to reduce the risk of whiskers that can lead to short circuits.

The metal in tin plating costs less than alternatives, such as silver and gold, and therefore typically has a lower cost but tin-plated busbars are a proven and reliable solution for applications where chemicals, moisture, salt, and dust are major concerns. They offer excellent resistance to oxidation and are widely used in many switchgear applications.

Improve durability

Durability is a key factor for efficient, cost-effective, and reliable power distribution systems. This requires busbars to perform effectively across a wide variety of applications and environments, including sliding and moving applications, joints, physical stress, and vibration.

If a busbar does not meet the requirements for these conditions, reliability is reduced and operations are affected. As a result, nickel-plated busbars are one of the preferred options for durable, high-quality busbars that can withstand harsh environments and applications involving movement.

Long term durability

Conditions change over time, and for many users of busbars, service life is just as important as the initial cost. Environmental and operational factors such as current load, temperature, and surrounding conditions can directly affect the service life of busbars, particularly at joints.

Therefore, it is not only important for the component to operate effectively today, but across its entire service life. This is why electroplated joints are preferred. The functional properties that electroplating provides, such as the low resistance offered by silver plating, remain stable and consistent over time, supporting long-term performance.

Decision-making is also a key determinant of reliability. Selecting the correct busbar material and coating, and matching them to the application and operating conditions, helps ensure durability.

Reduce build-up of dust

While performance characteristics such as conductivity and low resistance are key factors when choosing busbars, safety is also critical. Power distribution systems must operate efficiently and safely.

A common issue for busbars used in data centre and outdoor applications is the build-up of dust. Dust accumulation increases the risk of fire, endangers operations, and indirectly increases maintenance requirements. More frequent maintenance also increases the risk of electrocution, as personnel are exposed to live voltage applications more often.

Electroplated busbars have a uniform and smooth surface, which reduces the likelihood of dust accumulation and static charge. Cleaning and maintenance are also easier, as plated surfaces can be wiped clean more effectively, improving overall system safety.

Reduce material usage

Nickel, silver, and tin electroplating processes make efficient use of raw materials and, in many cases, reduce the total amount of material required. This benefits both cost control and sustainability for projects that use busbars and electrical connections.

According to suppliers and end users of low- and medium-voltage applications, un-plated busbar connections often require significantly more copper to carry the required current. Electroplating increases the allowable temperature rise limit, which means less copper is needed to achieve the same performance, at a time when the price of copper continues to rise

Budget and cost management

Where budget is a consideration, engineers may opt for aluminium instead of copper. This is made possible through the benefits of surface finishing. Although aluminium busbars do not have the same conductivity as copper busbars -nickel, silver, and tin plating improve conductivity and enable aluminium busbars to be used instead of copper, resulting in cost and weight savings.

While additional processes such as busbar plating do add to component costs, which can lead some users to rely on uncoated busbars, various studies show that the costs associated with corrosion, replacement, energy loss, and reduced conductivity are often significantly higher than the cost of plating processes themselves, particularly tin plating.

Lighter assemblies

As mentioned above, these benefits extend to applications where weight is a critical factor. Copper is over 300% heavier than aluminium, meaning that by using aluminium, users benefit from easier installation and reduced transportation costs while still achieving the performance required for power systems.

This approach is common in aerospace, automotive, and marine applications, where lightweight materials are preferred for performance and operability.

Allowing joints

According to industry experts and users of busbars worldwide, manufacturers tend to favour plated busbar joints over un-plated ones, largely due to material efficiency. Using uncoated joints often requires significantly more material, sometimes up to double the amount, compared with busbars treated with silver or tin surface finishes.

Reliable electrical contact under sliding or rotational motion

Bare busbars can be unsuitable for applications involving movement, as the surface can be damaged due to a lack of wear and friction resistance. In contrast, busbars that have undergone dual plating processes, such as nickel followed by tin, benefit from increased wear and friction protection as well as improved corrosion resistance. This results in more durable and reliable busbars in applications involving sliding or rotational movement.

Ease of maintenance

To perform effectively and meet durability requirements, busbars require ongoing maintenance. In many cases, maintenance directly influences the long-term reliability of power systems.

Un-plated busbars can often result in higher overall costs, not only due to increased energy loss, reduced electrical flow, and overheating, but also because of more frequent inspections and maintenance. These increased maintenance requirements add to operational costs over time.

Compliance

Busbar plating directly helps manufacturers comply with safety, quality, and sustainability standards. For example, electroplating helps busbar manufacturers meet the temperature rise and corrosion resistance requirements defined under IEC 61439 performance verification.

Wider applications

Surface treatments allow busbars to be used in a wide range of applications than would otherwise be technically feasible or cost‑effective. From facilitating the growth of AI, to powering your local substation, to charging your new electric vehicle, and enabling renewables – busbar plating is vital to successful long-term deployment of modern technologies.

Busbar plating processes

Across modern power distribution systems, busbar performance is no longer determined by base material alone. Electrical resistance at joints, temperature rise under load, exposure to oxidation and contamination, mechanical wear in moving or vibrating assemblies, compliance with standards, long-term durability, and material efficiency all influence reliability, safety, and lifetime cost. As demonstrated above, surface finishing and electroplating play a functional role in addressing these challenges, supporting stable electrical contact, controlled thermal performance, improved wear resistance, and extended service life across a wide range of operating environments.

For advice on surface finishing and busbar treatment, get in touch with Karas Plating – your busbar plating experts serving customers worldwide. We offer a wide range of industry-leading busbar plating processes, including nickel, silver, and tin – each tailored to your specific application. Whatever your industry or use case, contact our specialist team today to arrange a consultation for your busbar plating requirements.