The demand for reliable, efficient, and scalable infrastructure in data centres has never been greater. At Karas, we provide specialised plating solutions to enhance the performance, durability, and reliability of critical data centre components. From server hardware to power distribution units, our processes are tailored to meet the exacting requirements of this fast-paced and essential sector.

Why is Plating Essential to Data Centres? Key Benefits

Plating offers significant advantages for data centre infrastructure, helping to optimise both performance and longevity.

Reduced Corrosion

Plating adds a protective layer that shields metal components from environmental factors, preventing degradation and ensuring long-term durability.

Oxidation Prevention

A high-quality finish prevents oxidation from forming on metal surfaces, maintaining consistent performance and reliability.

Increased Reliability of Components

Surface coatings enhance the strength and resilience of components, extending their operational lifespan and ensuring dependable performance.

Enhanced Transfer Speeds

High-performance plating improves conductivity, enabling faster and more efficient transmission of power and data.

Minimised Energy Loss

Surface finishes reduce energy dissipation, ensuring maximum efficiency across data centre infrastructure.

Versatility

Electroplating can be applied to a wide range of metals, including specialist alloys that offer superior conductivity and require minimal preparation.

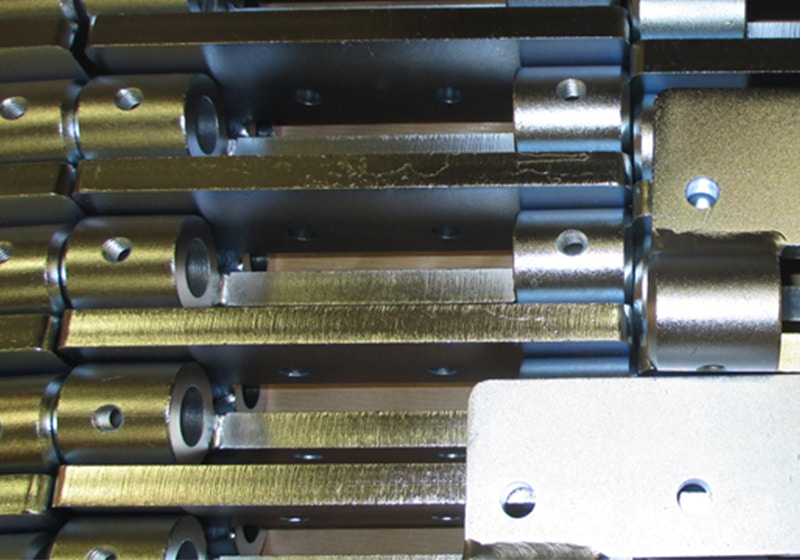

Components We Plate

Our surface finishes enhance the performance and durability of a wide variety of data centre components, including:

Power Distribution and Cabling

- Busbars: Plating enhances the conductivity and corrosion resistance of busbars, a space-saving and efficient alternative to traditional cables.

- Cable Trays and Racks: Processes such as Zinc plating protect against corrosion, ensuring long-lasting performance.

- Threaded Rods: Plating improves the corrosion resistance and durability of threaded rods, ensuring they perform reliably in critical infrastructure applications.

Server and Network Equipment

- Chassis and Enclosures: Enhanced durability and appearance.

- Switch and Router Chassis: Improved corrosion resistance for network-critical components.

- Network Interface Cards (NICs): Enhanced conductivity for faster network speeds.

- Memory Modules: Reliable performance with optimised conductivity.

Cooling and Heat Management

- Fans and Blowers: Nickel plating enhances durability and corrosion resistance.

- Heatsinks and Processor Heat Spreaders: Improved thermal conductivity for effective heat dissipation.

Storage Devices

- Hard Drives and SSDs: Enhanced protection and durability for critical storage components.

Additional Components

- Brackets and Frames: Reinforced for long-term reliability.

- Enclosure Hardware: Durable finishes that improve aesthetics and longevity.

- Flooring and I/O Shields: Protected against wear and tear for high-use areas.

Why Choose Karas?

We deliver high-quality plating solutions that optimise the performance and longevity of your components. Here’s what makes our services stand out:

Substrate Cleaning

We ensure all components are properly cleaned and prepared before plating for optimal adhesion and performance.

Wide Range of Plating Processes

We offer electroless nickel, silver, gold, copper, tin, and zinc plating. Each is chosen to suit the specific requirements of the component and application.

Small and Large Components

Whether your needs involve intricate components or large-scale items, we provide both rack and barrel plating solutions.

Custom Solutions

Have unique requirements or challenges? We work with you to develop tailored solutions that solve your problems effectively.

Experience and Expertise

With decades of specialised knowledge, we understand the demands of the data centre sector.

Our Accreditations

ISO 45001:2018 – Health & Safety

ISO 45001:2018 is the international standard for Occupational Health and Safety Management Systems (OHSMS), replacing OHSAS 18001. By working to this standard, we protect the health, safety, and wellbeing of our employees, visitors, and anyone affected by our operations

ISO 14001:2015 – Environment

ISO 14001 is an internationally recognised standard that sets the requirements for an environmental management system (EMS). By working to the ISO 14001:2015 standard, we improve our environmental performance through the efficient use of resources and waste reduction, while strengthening our position and building trust with our stakeholders.

ISO 9001:2015 – Quality

ISO 9001 is the international standard for Quality Management Systems (QMS). By working to this standard, we strengthen our practices to meet the needs of our customers and stakeholders, using a framework that drives continuous improvement. It ensures we deliver consistent quality in our electroplating services through the correct application of a QMS.

Other sectors we cover

The automotive industry uses plated components to make their vehicles more efficient at every stage of their manufacture. From gold-plated micro-components in the ECU, to nickel-plated, corrosion-resistant parts, all the way to metal-plated plastic parts to create lightweight bodywork.

When using metal plating techniques in the electrical and electronic sectors, the two key concerns are precision and conductivity. Often you have to risk one in order to benefit from the other. This is where our expertise comes in, balancing the pros and cons of each metal, in order to deliver electronic components that work the way you need them to.

Whether we’re talking about the National Grid, criss-crossing the country providing the nation with its electricity, or more renewable sources of power generation like wind turbines and solar panels, electroplating is essential to the power industry. Components undergo great pressure on a day-to-day basis and must be robust enough to withstand the strain.

All manner of medical equipment needs reliable electroplating solutions in order to do their job. From sterile surgical instruments to components for larger pieces of medical apparatus, the quality of our plating techniques can literally affect lives.

The petrochemical industry produces essential items that we use everyday, from plastics, petroleum, and detergents to lubricants, asphalt, propane, and more. Raw materials are subjected to extreme heat and pressure throughout the refining process, so the machinery used to do so requires durable and reliable plating to get the job done.

The British defence industry utilises many of the electroplating processes that we have perfected here at Karas Plating. Precision plating is required to create reliable defence products. Likewise, they must be resistant to heat, corrosion, and other environmental considerations, since they might be deployed anywhere in the world at a moment’s notice.