The term engineering covers a wide variety of disciplines across multiple industries. Most manufacturing and technological sectors have significant involvement from a team of engineers. We work alongside many of these companies, whether they are in automotive, aerospace, defence, medical, or any one of a hundred other industries.

While the work they do might differ from one sector to another, there are certain engineering principles that hold true across all industries. Here at Karas Plating, we follow many of those principles ourselves, when formulating and operating out our extensive selection of plating solutions.

The Significance of Electroplating in Engineering

So, why have we put aside a separate page for engineers if they fall into those other industries? Largely because they will be the ones to decide which plating finish is best-suited to their current projects. While the designers might insist that the component parts have certain qualities and the management team might sign off on the final decision, it is the engineers who will use their technical expertise and experience to work out the most effective plating method for their project.

Benefits of Plating for Engineering

The addition of metal plating to your component parts is a simple and cost-effective way to impart certain qualities to those components. Whether you want to make them more durable, more corrosion-resistant, better at conducting electricity, or anything else, there is always a plating solution for you. These are some of the beneficial qualities that plating can provide:

Corrosion resistance

Many forms of electroplating help to protect your substrate against corrosion. This is a desirable quality for any engineering project, but particularly for those likely to suffer extreme atmospheric conditions. This makes plating a crucial part of many petrochemical, aerospace, and automotive engineering works.

Wear and Abrasion Resistance

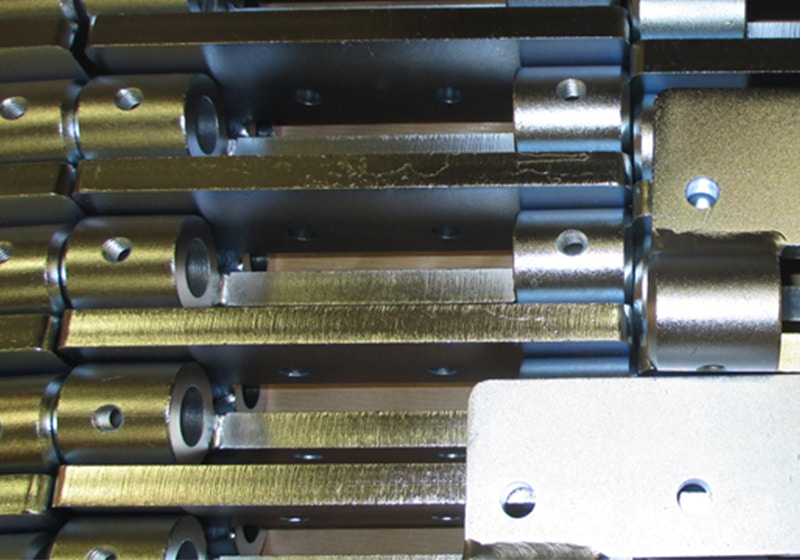

If your engineering project involves moving parts, there is a strong likelihood that these will be rubbing against one another, simply as part of their day-to-day operation. The right metal plating slows down abrasion and wear, making your components more durable. Not only will this limit the damage from wear and abrasion, it will also mean your components are less likely to suffer damage if dropped.

Thickness

Some engineering projects require parts of a certain thickness, but the substrate is either too heavy or too expensive to offer a cost-effective solution. There are several plating options that can be employed to increase the thickness of the component parts. Many of these impart further benefits, such as increased durability and lifespan.

Solderability

An easy and effective way to improve the solderability of your components is to use an appropriate form of metal plating. This allows you to retain the core strength and hardness of your substrate, whilst also offering easier and more reliable soldering.

Heat Resistance

If your engineering project involves high temperatures – such as those you might find in an engine or other combustible environment – you will need to protect them with a heat-resistant form of plating. Zinc-nickel alloys and gold plating are two of the most popular methods for achieving this.

Electrical Conductivity

Reduced Friction

As well as causing wear and abrasion damage, moving parts in your engineering project can also result in excessive friction, which results in raised temperatures. Certain forms of plating, such as nickel plating, help to reduce friction in these circumstances, lessening the chance of overheating.

Adhesion

Certain metals – particularly copper – are often applied as a base layer of plating, as they offer superior adhesion compared to the substrate. Doing so improves the uniformity of the surface and the appearance of the final finish, as well as providing a more effective surface for paints, as well as other electroplating techniques.

Torque Tolerance

The right kind of metal coating can help to strengthen the substrate of your components, allowing it to display greater tolerance to torque without becoming damaged or breaking. This is a desirable quality for any engineering project that puts its constituent parts under considerable strain.

Types of Electroplating for Engineers

Once you know the composition of your substrate and the qualities you wish to confer to it, you are able to make a decision on the appropriate plating material to achieve that goal. At Karas Plating, we offer a wide range of plating options to our engineering customers from all over the UK. These are some of our most popular methods:

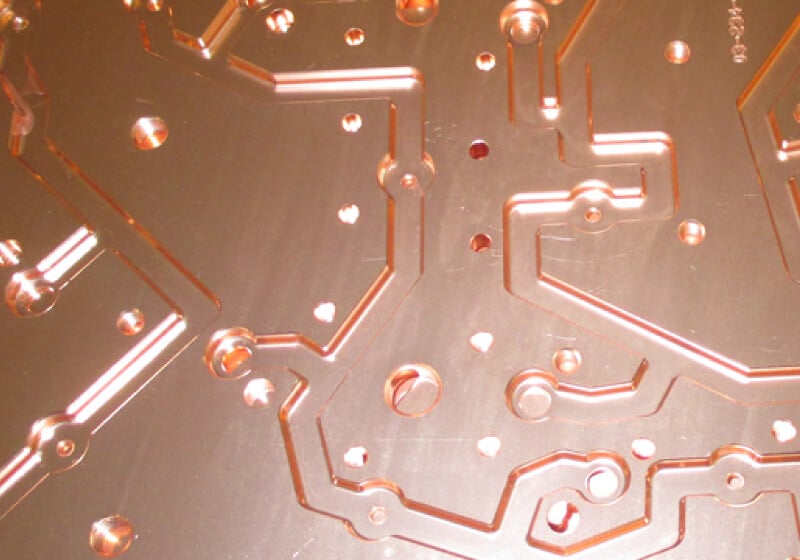

Copper is a useful metal for plating purposes, being both flexible and highly-conductive, which makes it a popular choice for plating electronic components. Often used by engineers working in the aerospace and defence industries, copper also provides extra thickness, protection against corrosions, and extremes in temperature. Since copper is an easy substance to plate, it is regularly used as an initial layer for additional plating or coating to be applied to.

Like any precious metals, gold plating can be expensive, but it is almost always worth the additional cost. Few other plating solutions offer the same high levels of improved conductivity or protection from corrosion, making it another strong choice for electrical engineering projects. Despite the fact that gold is considered a soft metal, in engineering applications it is resistant to both heat and wear.

Nickel is one of the most popular forms of electroplating, thanks to its high wear resistance and corrosion resistance. It is often applied as a sacrificial layer to other metals, forming a tight, air-proof barrier to protect against oxidisation. Many engineers choose nickel plating for steel components as a more cost-effective alternative to using stainless steel.

Much like gold, silver is another precious metal, well-known in engineering circles for its conductive properties (both in terms of heat and electricity). Furthermore, it also boasts great corrosion resistance and is stronger and more durable than gold. It is particularly useful in the power generation industry, where fast, reliable conduction is highly-prized by that sector’s engineers.

If your engineering budget doesn’t stretch to gold or silver for plating your electronic components, tin can provide a cost-effective alternative. Hardware manufacturers across the UK make use of tin-plating, benefiting from its good levels of conductivity, as well as its corrosion resistance and solderability. Tin is softer than most coating metals and is prone to whiskering, though this can be remedied by using a bright tin plating technique.

Zinc is used most often as part of a zinc-nickel alloy, though it can be used as a solo metal plating technique. On its own, zinc offers great adhesion for paints and primers, and is often more affordable than some of the more popular metals. It has many plating applications, being compatible with a wide range of base metals.

Metal Plating Techniques

As well as deciding on the type of metal for your plating solution, it is worth considering the appropriate method of application. Generally speaking there are three main ways of plating your substrate: barrel plating, rack plating, and brush plating.

Barrel plating is a popular method of plating smaller components that are unlikely to suffer damage if they come into contact with one another. The parts are loaded into a cylinder, which is then filled with the appropriate solution for the finishing process, until all the components are submerged. The cylinder – or barrel (hence the name) – is then rotated, to ensure that all parts receive an equal and even coating. A key advantage of barrel plating is that the parts do not all have to be the same. Multiple components of different sizes and shapes can be loaded into the barrel to receive treatment at the same time.

If the parts that need plating are on the large side, or too fragile to risk being rotated in a barrel with a load of other components, the rack plating technique might be more appropriate. As the name suggests, for this method parts are arranged individually on a rack and gently lowered into a solution bath. Prior to being submerged, each part must be directly connected to the electrical source to allow for effective coating. While this process is more expensive than the barrel plating technique, it is the best option for those components that could be damaged during rotation.

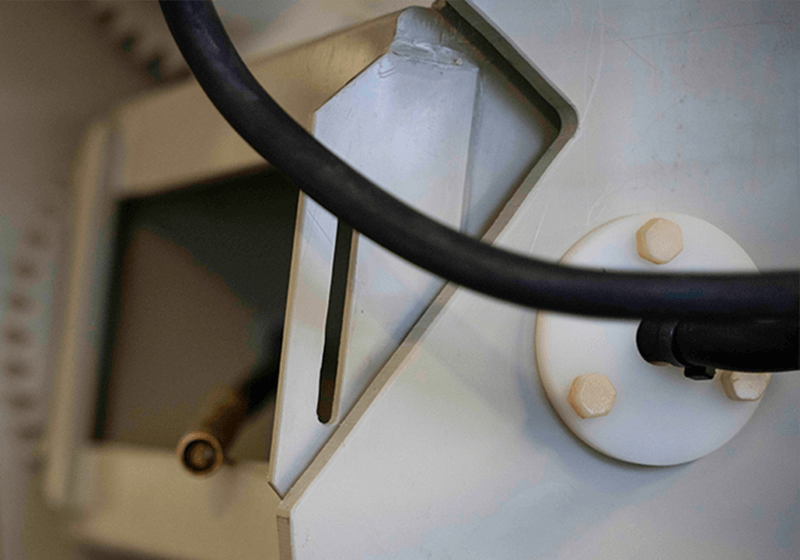

A third option for applying metal plating is brush plating. This method does not rely on submerging the parts in a solution bath, but rather on targeting individual areas on the substrate. As such, it is an electroless plating technique, where the metal coating is formed via a chemical reaction, with the solution applied to the target area with a specially-treated brush. This process is slower, often requiring several passes to build up a layer of suitable thickness.

Choosing the Right Plating Provider

As an engineer, you are concerned with getting the right plating results for your project, but how can you be sure that the plating company you choose can meet your specifications? Here at Karas Plating, we are always open and honest with our customers. These are some of the things you should always raise with your plating provider prior to signing a contract.

Size

Larger components, such as panels and framework, need to be submerged using the rack technique described above, as they will not comfortably fit into one of our plating barrels. When looking for the right plating company, it is important to confirm that their plating facility has the capacity to handle your largest components. At Karas Plating, we regularly plate large substrates for engineers in all manner of industries, so we are confident we will be able to accommodate you.

Volume of Parts

Likewise, when it comes to large orders of smaller components, you need to know that your plating company can handle the volume of parts required. We provide barrel plating services for companies across the UK, coating hundreds and thousands of components at a time. We have a large capacity, sufficient to fill even the most ambitious of orders. Our plating technicians are available to work in shifts to ensure that large volume orders are completed in a timely manner.

Project Budget

On of the most important considerations, when choosing your plating provider, is whether they can fulfil your order inside your existing engineering budget. Here at Karas Plating, we do all we can to be cost-effective and competitive with our pricing structure. All our charges are provided up front, with no hidden fees or extras to follow. We will also provide you with a free, no-obligation quote for our services upon request.

Desired Metal Coating

Not every plating company can handle every kind of plating process. It is important that your provider confirms from the outset whether they can meet your particular requirements. It is also worth considering whether your provider will be able to fulfil any future orders for engineering projects already in the planning stage. At Karas Plating, we will always inform you whether we have the materials and experience to meet your plating specifications. We presently offer a wide variety of metal coatings, including bright tin plating, copper plating, dull tin plating, electroless nickel plating, gold plating, iriditing, manganese phosphate coating, silver plating, zinc-nickel plating, zinc plating and colour passivates.

Preparation Capabilities

Many electroplating companies are focussed solely on the plating processes themselves, requiring their engineering customers to prepare the substrate. The downside to this, of course, is that not all customers are plating experts and lack the technical expertise or the equipment to properly clean and prepare their components to an acceptable standard. Here at Karas Plating, all preparation work is performed in-house to ensure all your components are clean, free from contaminants, and ready to receive an effective plating solution.

Other sectors we cover

The automotive industry uses plated components to make their vehicles more efficient at every stage of their manufacture. From gold-plated micro-components in the ECU, to nickel-plated, corrosion-resistant parts, all the way to metal-plated plastic parts to create lightweight bodywork.

When using metal plating techniques in the electrical and electronic sectors, the two key concerns are precision and conductivity. Often you have to risk one in order to benefit from the other. This is where our expertise comes in, balancing the pros and cons of each metal, in order to deliver electronic components that work the way you need them to.

Whether we’re talking about the National Grid, criss-crossing the country providing the nation with its electricity, or more renewable sources of power generation like wind turbines and solar panels, electroplating is essential to the power industry. Components undergo great pressure on a day-to-day basis and must be robust enough to withstand the strain.

All manner of medical equipment needs reliable electroplating solutions in order to do their job. From sterile surgical instruments to components for larger pieces of medical apparatus, the quality of our plating techniques can literally affect lives.

The petrochemical industry produces essential items that we use everyday, from plastics, petroleum, and detergents to lubricants, asphalt, propane, and more. Raw materials are subjected to extreme heat and pressure throughout the refining process, so the machinery used to do so requires durable and reliable plating to get the job done.

The British defence industry utilises many of the electroplating processes that we have perfected here at Karas Plating. Precision plating is required to create reliable defence products. Likewise, they must be resistant to heat, corrosion, and other environmental considerations, since they might be deployed anywhere in the world at a moment’s notice.