It’s hard to think of any industry in the UK that doesn’t benefit from electroplating in one form or another. From car assembly lines to oil rigs, from mobile phones to ventilators, metal finishing, surface coating, and electroplating plays a pivotal role in every sector of our daily lives.

Here at Karas Plating, we work alongside industry leaders across most of those sectors, producing and delivering exceptional plated components to clients in every industry. Our metal finishing facility in Leigh operates on a 24-hour basis, creating plated materials of the highest possibility.

As seasoned professionals with a seven-decade trading history, we understand better than anyone what our clients are looking for when it comes to electroplating: a fast, efficient service, consistent quality, and technical know-how. Here at Karas Plating, we provide all three, no matter what sector you’re in.

These are just a handful of the industry sectors to whom we provide essential plated components.

The automotive industry uses plated components to make their vehicles more efficient at every stage of their manufacture. From gold-plated micro-components in the ECU, to nickel-plated, corrosion-resistant parts, all the way to metal-plated plastic parts to create lightweight bodywork.

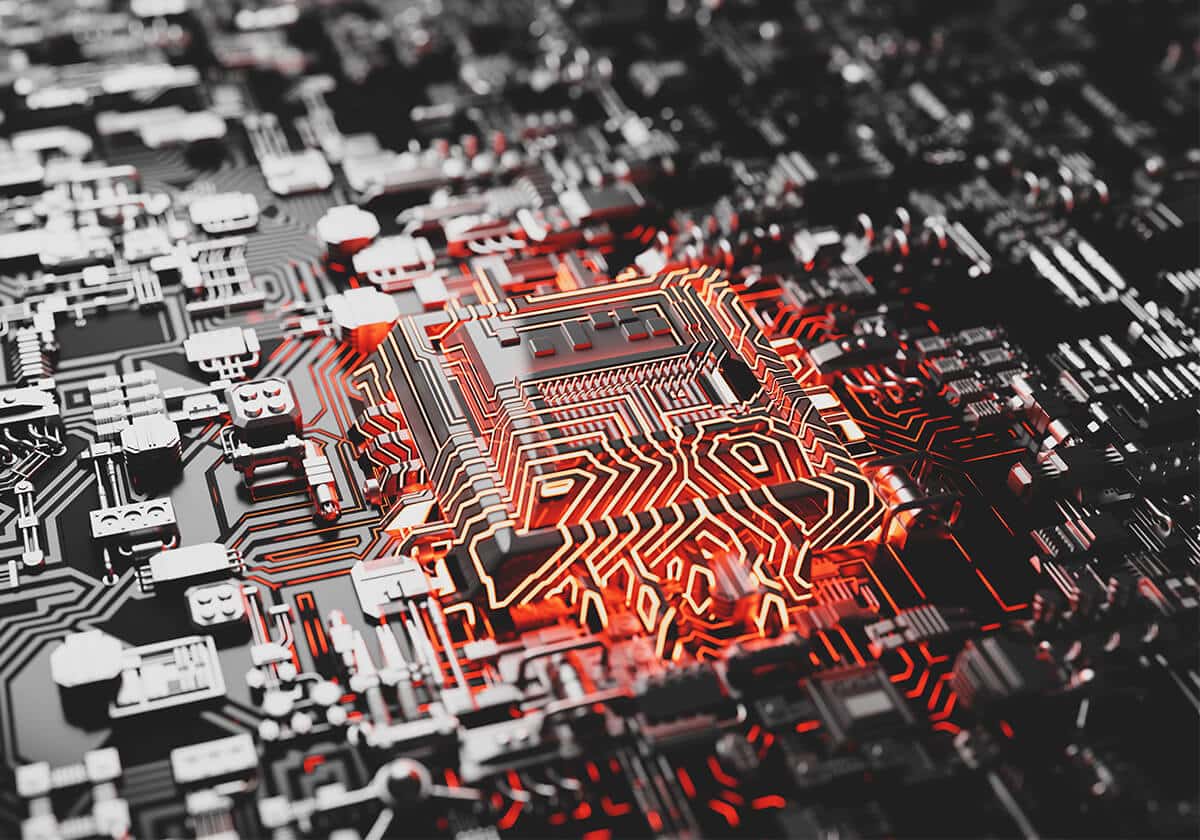

When using metal plating techniques in the electrical and electronic sectors, the two key concerns are precision and conductivity. Often you have to risk one in order to benefit from the other. This is where our expertise comes in, balancing the pros and cons of each metal, in order to deliver electronic components that work the way you need them to.

Whether we’re talking about the National Grid, criss-crossing the country providing the nation with its electricity, or more renewable sources of power generation like wind turbines and solar panels, electroplating is essential to the power industry. Components undergo great pressure on a day-to-day basis and must be robust enough to withstand the strain.

All manner of medical equipment needs reliable electroplating solutions in order to do their job. From sterile surgical instruments to components for larger pieces of medical apparatus, the quality of our plating techniques can literally affect lives.

The petrochemical industry produces essential items that we use everyday, from plastics, petroleum, and detergents to lubricants, asphalt, propane, and more. Raw materials are subjected to extreme heat and pressure throughout the refining process, so the machinery used to do so requires durable and reliable plating to get the job done.

The British defence industry utilises many of the electroplating processes that we have perfected here at Karas Plating. Precision plating is required to create reliable defence products. Likewise, they must be resistant to heat, corrosion, and other environmental considerations, since they might be deployed anywhere in the world at a moment’s notice.

Much like the automotive industry, the British aerospace sector relies on a wide variety of plating techniques at every stage of production. From making their components more hard wearing or resistant to corrosion, to improving the conductivity of electronic equipment, all aspects of the aerospace industry require the very best in professional metal finishing and plating, as provided by the Karas Plating team.

Of course, many of the other industry sectors mentioned on this pages involve some measure of engineering. However, engineering is an umbrella term that covers dozens of other industries not listed here. Whatever sector you are involved in as an engineer, you will need quality plating services to improve the shelf life or performance of your products. Luckily, at Karas Plating, we can help you find the perfect solution.

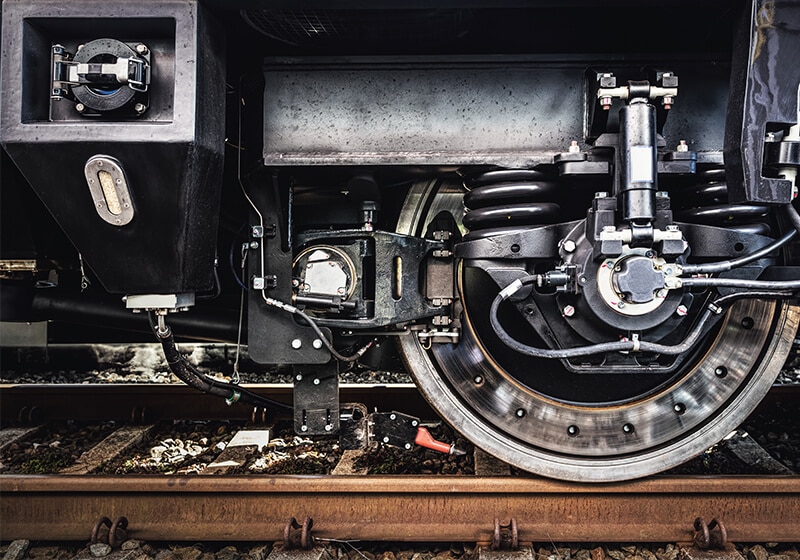

The UKs rail and transportation industry depends upon electroplating to protect its component parts from the harsh environmental conditions they must endure every day. These components need to be resistant to both oxidation and cold, as well as all extremes of temperature. Conductive electroplating methods are also essential to ensure the accuracy of the many electronic applications used in the industry.

If components used in the power generation industry are under stress, it is nothing compared to the oil and gas sector. From North Sea oil rigs, to natural gas extraction centres, through to the pipeline infrastructure that gets it to hundreds of sites across the country for processing, the industry needs plated materials that can survive in the harshest of environments.

In today’s technologically advanced world, most electronic components are tiny but still require reliable plating, delivered in volume to cover thousands of electronic parts at a time. Thanks to our rack-and-barrel plating methods and decades of experience in the field, we can provide a cost-effective solution to all your electronic plating needs.

Electrification is one of the newest sectors we provide quality plating for, but it’s one that’s only going to get bigger as the country moves away from its reliance on fossil fuels. It covers various forms of charging large electrical appliances, such as electric cars and hybrid vehicles, and requires a high standard of electroplating to achieve optimal efficiency.

As well as power generation, electroplating is much in demand in the energy distribution sector. Whether dealing with solid fuel, liquid gas and oil, or electrical power, getting the energy to its intended targets takes a toll on the supply chain. The right plating techniques can help make the distribution infrastructure more efficient and durable.

The food and drink industry relies on high-quality electroplating solutions to keep the people of Britain fed. Production machinery runs day and night and requires components that can withstand that kind of wear, as well as ones that are resistant to the corrosive effects of salts, oils, and liquids used in the production process.

Pharmaceutical companies use plating services in both their research and development laboratories as well as their production centres, and we can supply the right plating solutions for either. These techniques can improve sanitation and precision in the lab and also ensure manufacturing machinery runs at optimal performance.

The telecommunications sector makes use of several plating methods to improve the solder-ability, conductivity, and durability of the many small electronic components used in modern phones, tablets, and other telecom devices.

Machinery used in the agriculture sector depends on quality electroplating methods to ensure it operates properly in cold and wet conditions. Plated parts are more resistant to corrosion and general wear, both major considerations for agricultural businesses.

Electroplating for the space industry is generally used to improve the strength and durability of onboard components and to protect satellites and other space equipment from the effects of cold, light, and radiation outside the Earth’s atmosphere.

The demand for reliable, efficient, and scalable infrastructure in data centres has never been greater. At Karas, we provide specialised plating solutions to enhance the performance, durability, and reliability of critical data centre components. From server hardware to power distribution units, our processes are tailored to meet the exacting requirements of this fast-paced and essential sector.