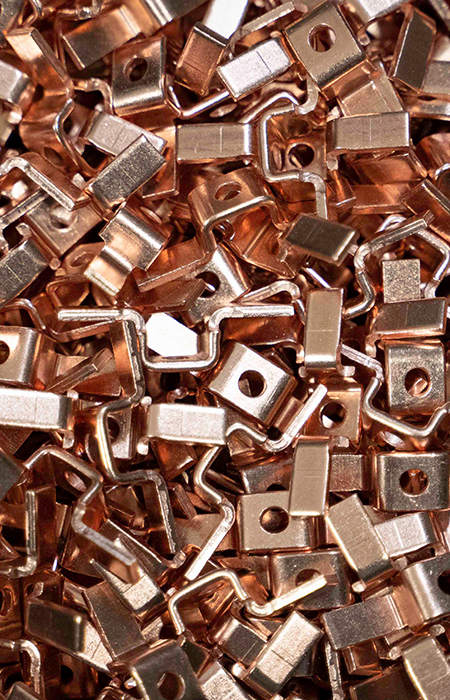

Gold plating is one of the most common metal plating services we provide here at Karas Plating. Absolutely crucial to the electronics industry, gold plating requires precision and expertise, both of which we have in abundance. Over the seventy years that we have been in business, our customers from all over the UK have recommended us to their colleagues and business partners because of the quality of gold plating we are capable of.

What is gold plating?

Gold plating describes any of several distinct techniques designed to fuse a thin layer of gold onto another base metal. There are a number of processes that can be utilised to do so, some of which involve electroplating and others that do not. At Karas Plating, we consider ourselves experts in all methods of gold plating, and our senior staff will be happy to discuss your best options with you when you call.

How does gold plating work?

Usually using silver or nickel as a substrate, gold can be applied either through electroplating or through electroless immersion. Whichever process is chosen, the base metal needs to be thoroughly cleaned and de-greased before application in order for the gold to properly fuse with the surface.

We employ a number of processes for this, from alkaline and acid washes, to chemical immersion and abrasions – whichever best suits the situation. An electrolyte solution is then made up, which will vary depending on the finished product.

Our metal finishing experts are more than familiar with the relevant chemistry involved in gold plating. Part of their initial discussion with you will concern the specific requirements you have of your finished components. This will include how conductive you need them to be, how heat resistant, how thick, and so on.

Based on your responses, we can calculate the best solution for plating your substrate. For softer applications, we will use pure gold extracted with a neutral gold cyanide solution. Where hardness is a factor, we will use a gold alloy (usually nickel or cobalt), which are more hard-wearing, but less conductive. These alloy platings are processed using acid gold plating techniques.

Applications of the gold plating process

Gold plating has obvious applications in the jewellery trade, offering a cheap but attractive alternative to solid gold jewellery.

On an industrial level, the main application is in electronics. Like the other noble metals, gold does not corrode, making it resistant to rusting over time.

Also, it is highly conductive for electricity, making it the perfect solution for many electronic applications.

Benefits of the gold plating process

Gold doesn’t just look nice; it has many practical properties that make it one of the most versatile and beneficial metals that we use on a regular basis. It is one of the metals that is least susceptible to the oxidation process. In other words, it is almost wholly-resistant to the problem of rusting and corrosion

Since oxidation also inhibits a metal’s ability to conduct electricity, gold’s natural resistance to this process make it a great conductive material for use in electronics, as does the smooth finish gold creates, allowed for flush connection plates. Another benefit is the metal malleability. For most gold plating projects, only the thinnest layer is required.

You get all of the benefits of the metal itself, but a thin deposit will be sufficient to make the most of them for electronic purposes. With gold being so malleable, it is easy to lay these ultra-thin deposits, thus saving money on what might otherwise be a costly project.

Despite being perceived as soft, gold is extremely durable, providing excellent resistance against regular wear and tear as well as excessive heat. Also, gold is less susceptible to fretting (that is the general wearing away of its surface over time due to friction) than most metals. All of these benefits combined produce a metal that seems custom made for use in consumer electronics.

a quality process

In common with the rest of the metal finishing processes performed at Karas Plating, our gold plating techniques are fully approved to ISO 9001 standards for Quality and ISO 14001 standards for Environmental. Whichever method we apply will be chosen to meet your specific specifications, as well as all industry standards.