How Silver Plating Improves Busbar Performance In Electric Vehicles

In this article, we look at why silver plated busbars continue to be specified in electric vehicle applications, how plating performance impacts efficiency and reliability, and what manufacturers need to consider when selecting plated finishes for EV battery systems.

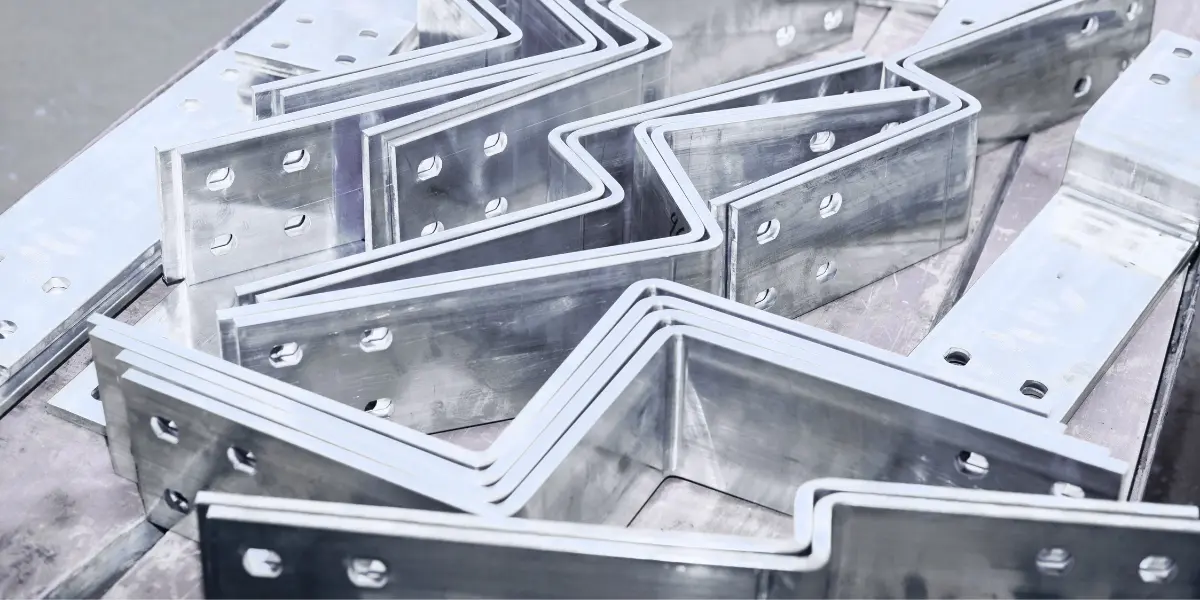

Busbars are a critical component within electric vehicle battery systems, responsible for carrying high currents between cells, modules, and power electronics with minimal losses.

As demand grows for greater efficiency and power density in automotive platforms, the electrical and thermal performance of these busbars becomes increasingly important.

Silver plating is widely used on EV busbars to reduce contact resistance, improve current carrying capability, stabilise joint performance, and maintain consistent performance under high load and repeated charge–discharge cycles. Compared to bare copper or alternative finishes, silver provides outstanding electrical conductivity at interfaces while supporting reliable, low-resistance connections in demanding automotive environments.

Why is silver plating for busbars crucial?

Conductivity

Silver plated busbars offer superior conductivity, which is essential as busbar connections play a critical role in overall electrical distribution performance. In fact, silver is one of the best metals for conducting electricity, making it key for evs.

Silver plated busbars support excellent electrical performance because silver is one of the best metals at conducting electricity, helping to minimise resistive losses where conductors and busbars interface. In EV powertrains, where high currents flow between the battery pack, inverters, and motor, low resistance current paths are essential for efficient power transfer and stable system operation.

Reduced electrical resistance

Silver plating is important because it reduces the electrical resistance of high-current busbar-to-busbar connections. A good busbar connection requires low contact resistance to minimise energy loss and improve reliability. By increasing the quality and performance of busbars, overall vehicle efficiency is improved.

Ductility

In EV applications where components are exposed to vibration and shock, a silver-plated layer provides a soft, conformal contact surface that maintains low resistance under repeated vibration and thermal expansion, helping joints remain stable and reliable over long service periods.

Contact resistance

Silver is a preferred choice for many high current applications such as EV battery systems, switchgear, and power distribution, often alongside alternative finishes like tin, depending on cost and performance needs. The silver layer acts as a barrier that shields the underlying copper or aluminium from direct oxidation, while itself providing a very low, stable contact resistance when correctly specified and maintained.

Silver plating for copper and aluminium busbars

Silver plating can be applied to both copper and aluminium busbars, opening new possibilities for manufacturers looking to utilise aluminium’s lightweight benefits while balancing conductivity and cost. Copper busbars are still the standard choice for many high current EV and power applications due to their excellent conductivity and mechanical properties, but on the other hand, aluminium is increasingly used where weight reduction is a key design driver.

Beyond Vehicles and into the charging infrastructure

Silver plating is not only used in electric vehicles. As EV adoption increases, the demand for charging infrastructure also grows, and many electric vehicle charging systems rely on electroplated components to ensure reliable, high-current performance.

In both on board chargers and off board DC fast charging equipment, silver and other conductive plating processes help maintain low resistance at connection points, improving thermal performance and long term reliability.

Find out more about plating for charging infrastructure here.

Your plating partner matters

Silver plating is sometimes viewed as a costly or avoidable step in EV busbar design. In practice, cost and complexity are often driven less by the plating itself and more by how it is specified, applied, and managed across the supply chain.

When silver plating is correctly engineered and delivered by an experienced plating partner, it remains a cost-effective way to achieve low contact resistance, thermal stability, and long-term reliability, particularly in high-current battery systems where connection integrity is critical.

Factors such as surface preparation, underlayer selection, plating thickness, masking, and post plate finishing all have a significant impact on performance, consistency, and lifetime cost.

When silver plating is correctly specified and carried out by an experienced busbar plating partner like Karas Plating, it remains a highly cost effective way to achieve low contact resistance, thermal stability, and long term reliability, particularly in high current battery systems where joint integrity is critical to safety and performance.

Why choose Karas Plating for silver plating of busbars?

Electroplating aluminium busbars with silver is less common than plating copper due to the technical challenges involved in surface preparation, adhesion, and long term stability. This is why many manufacturers rely on Karas Plating for custom busbar plating processes specifically to address these challenges, producing components with durable, uniform silver finishes applied to tightly controlled micron thicknesses.

We are well equipped to support both aluminium and copper busbars, and we can recommend suitable processes such as nickel under-plating to manage thermal stress and prevent diffusion. Our processes also include cleaning, pretreatment and underlayer options needed for aluminium busbars.

All the silver busbar electroplating processes at Karas Plating are carried out in compliance with ISO 9001 standards for Quality and ISO 14001 standards for Environmental. What this means for you, our customers, is plated components of the very highest possible quality.

Our busbar plating processes are fully bespoke, with support for specific plating thicknesses, defined plating areas on the bar, and the choice between single coat and dual layer processes such as nickel-tin to match your electrical and environmental requirements.