Particularly in demand in both the electronics and electrical industries, bright tin plating offers excellent conductivity – essential for this sector. For more than seventy years, we have been providing clients across the country with exceptional bright tin plating on a wide variety of products and components.

What is bright tin plating?

Bright tin plating works in much the same way as its sister application – dull (or matte) tin plating. It is a method of electroplating that deposits a thin layer of tin across the target metal components. It differs somewhat from dull tin plating, in that the particles of tin that are deposited are smaller than those in the dull tin plating process. These small particles of tin are what give the process its distinctive bright finish.

How does bright tin plating work?

As with dull tin plating, the first step is to thoroughly clean the target metal or substrate, as any surface contaminants will impede the plating process.

Once we are satisfied that this has been completed, we select a solution best suited to the job’s specifications. There are several solutions we can use in this process, including methyl sulphuric acid, alkaline tin, or acid tin.

The substrate metal is then lowered into the bath of solution, where it will act as the cathode for the electroplating process. A direct current is fed into the bath, drawing the particles of tin to the substrate, where they will adhere to the base metal.

Applications of the bright tin plating process

Bright tin plating has several applications across a number of industry sectors.

Most commonly used by the electronics sector, its resistance to corrosion and excellent conductivity make it a solid choice for the electrical transmission and power distribution industries, too.

Bright tin plating can also be found in regular use as part of the food industry, telecommunications sector, and medical industry, as well as both marine and aerospace sectors.

Benefits of the bright tin plating process

Bright tin plating is a versatile technique, capable of being applied to a multitude of different base metals.

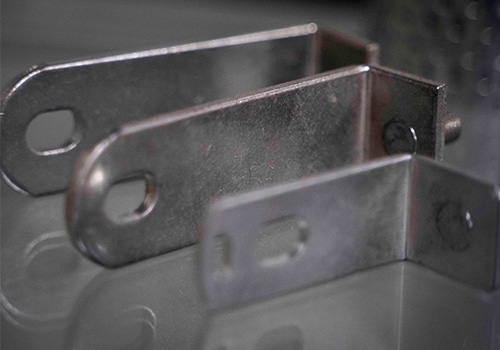

These include stainless steel, regular steel, aluminium, copper, brass, and zinc, among others. Bright tin plating also offers superb conductive properties, and exceptional corrosion-resistance.

The bright and shiny finish that results from the process is both aesthetically pleasing, and easy to solder, part of the reason that it is in such demand throughout the electronics industry.