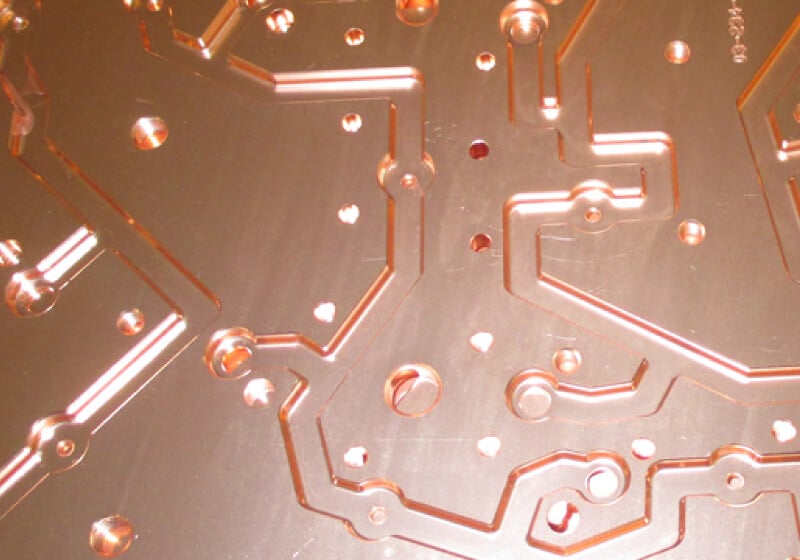

GOLD PLATING

There are many ways to plate a base metal with gold and, here at Karas Plating, we are well-versed in all of them, producing exceptional results every time. Gold-plated components are of immense use within the electronics industry. This is largely due to the plating’s heat and corrosion resistance, as well as its high levels of conductivity. A versatile plating technique, it remains one of our most popular processes.

MANGANESE PHOSPHATE COATING

Manganese phosphate coating is a process that is used on steel and iron products alone. By submerging the base components into a diluted phosphoric acid solution, we produce a hard-wearing and resilient coating with a unique crystalline structure. Its natural resistance to friction gives it many applications.

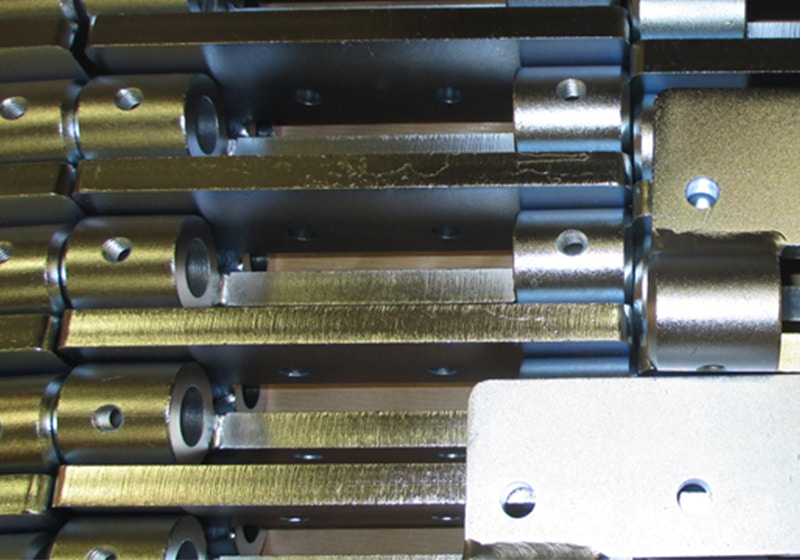

RACK AND BARREL PLATING

We provide both rack and barrel plating techniques to create smooth and even finish to your various components. We use rack plating for larger components, slotting them into a static metal rack to keep them steady during the plating process. Barrel plating is better used for smaller components, as it can hold dozens, if not hundreds during each application.

Busbar Plating

Busbars are an essential component used in all manner of applications from electric vehicles to power generation and distribution. They require high-quality plating processes to improve conductivity, as well as protect against wear, heat, and corrosion. We provide a variety of plating solutions for copper, aluminium, and copper-clad aluminium (CCA) busbars.

What Karas Plating can do for you

Here at Karas, we deliver an extensive range of finishing processes to our clients all over the country. Whatever your specific requirements might be, we have the tools, the materials and, above all, the expertise to meet them in full.

Based in the historic town of Leigh in Greater Manchester, we provide electroplating, surface coating, and metal finishing processes to clients across the UK. With more than seventy years in the industry, we have a reputation for excellence that is well-earned. We employ a “four cornerstones” work ethic that ensures the highest standards of quality and service.

Why choose Karas Plating for your electroplating, surface coating, and metal finishing needs?

Over the last 70+ years, we have established ourselves as a name to be relied upon in the plating industry. Our “four cornerstones” philosophy ensures that our clients are at the forefront of everything we do as a business.

STAY IN TOUCH